Enlightening Plast, as a leading PET bottle preform manufacturer, makes high-quality PET preforms—space-saving bottle preforms that reduce transport costs and improve production efficiency when blown into final shapes. With over 25 years of manufacturing expertise, we supply a complete range of weights, neck options (PCO 1810/1811, 30/25), and multiple colors and shapes.

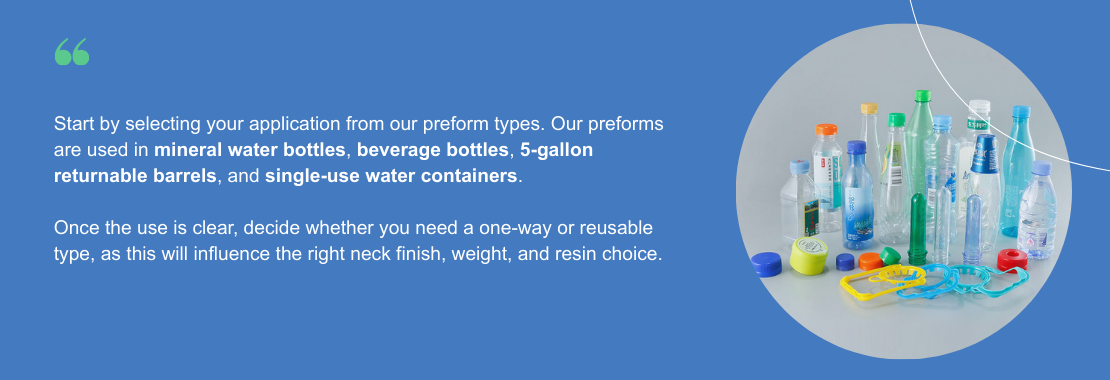

Our preform solutions cover diverse applications, from beverage bottles and 5-gallon water bottles to single-use packaging. We also provide rPET content up to 100% and full customization from resin choice to final color, ensuring both flexibility and sustainability for your supply chain.

Compared with finished bottles, preforms take up less space in shipping and storage. This directly reduces freight costs and keeps bulk orders more profitable. They also cost significantly less than traditional PC barrels, giving you a clear price advantage in large-volume packaging.

Made of PET material, our preforms feature glass-like clarity and smooth gloss. Multiple color options ensure your brand stands out with a clean, high-quality look. All products are BPA Free and DEHP Free, ensuring food-grade safety and compliance with international standards.

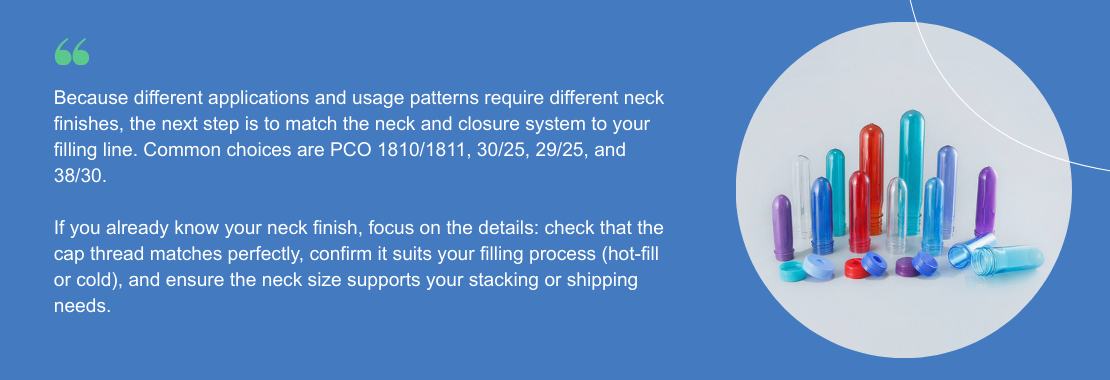

From 28mm to 120mm, our PET preforms cover all mainstream neck types. Each preform can be blown into bottles of different sizes and shapes, giving you real flexibility in one reliable supply.

Our pet plastic preforms are designed for seamless use with standard blow molding equipment. They run smoothly on existing lines, saving setup time and keeping production efficient.

We provide strong pre-sales support with 100% free samples, globally recognized certifications (FDA, EU 10/2011), and flexible customization on neck sizes, weights, and colors. Every detail is aligned with your project requirements before mass production.

Our after-sales service guarantees smooth cooperation through fast delivery within 7–15 days, 24/7 support, and a 3-year quality warranty on all preforms. We ensure your supply chain stays reliable and uninterrupted worldwide.

We use high-grade PET sourced from Sinopec, Lotte, and ExxonMobil, ensuring stable quality and low defect rates. Each batch passes strict quality checks, giving you preforms with consistent clarity, durability, and safety for global food and beverage packaging.

Our preforms are injection-molded on 20 Haitian machines inside a cleanroom workshop. The facility is divided into raw materials, production, packaging, and storage zones. With full- and semi-automatic blowing lines plus PET packaging lines, we ensure efficiency and hygiene.

We operate five factories across Shanghai, Guangdong, Jiangsu, Qingdao, and Hebei, covering 90,000 sqm. With 200+ preform molds and daily capacity above 10,000 units, we deliver bulk orders reliably, supporting industries from beverages and edible oil to consumer goods.

We provide complete customization, including preform design, mold development, neck sizes, weights, and colors. Handles, caps, closures can also be tailored. Advanced options such as UV-blocking, lightweight designs, and rPET content support branding and sustainability.

Didn’t find the exact preform you need? We have many more models and neck types not listed online — contact us to get full specifications and support.